Profile for expansion joints on floors, made of coextruded PVC, formed by body, rigid and flexible, which allows to absorb small variations of movement offering good resistance.

The combination of rigid and flexible material facilitates that the joint fulfills the function of absorbing the movement of the floor or covering, avoiding pathologies. It is ideal for your indoor or outdoor installation and all types of projects. Especially designed for floors of great thickness like terraces, marbles, etc.

--

--

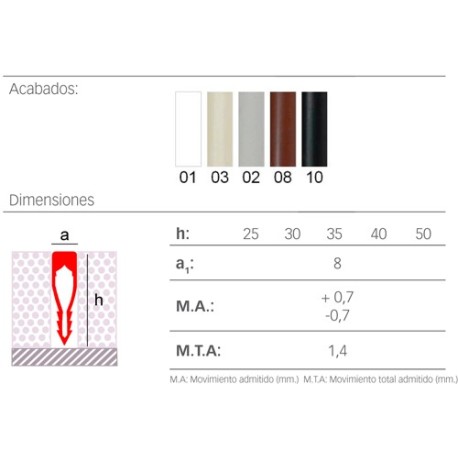

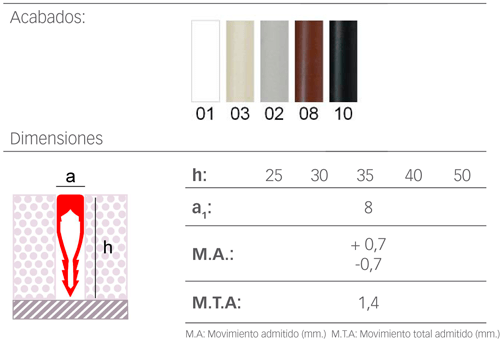

Dimensions:

- a: 8 mm.

- h: 25,30,35,40,50 mm.

- Long: 2.50 m

Applications

floor separation board whose main function is to absorb the expansion movements and contraction of the floor in order to avoid the appearance of pathologies in the installations. It can be placed vertically and horizontally both on floors and cladding.

Technical characteristics and tests

- Resistance to smoke: M2 (NBE-CPI-96)

- Abrasion resistance: Very good

- Working temperature: -10ºC / 60ºC

- Resistance to chemical agents: Buena except with chromic acid, sulfuric or nitric concentrates and organic solvents such as acetate and toluene - AIMPLAS

Materiales

Profile manufactured by coextrusion of PVC-P (rigid PVC) and PVC-U (PVC flexible). The PVC-U makes it easier for the profile to absorb expansion movements and contraction of the floor or the covering where the PVC-P is installed, due to its greater rigidity, for the baldoa support. PVC (polyvinyl chloride), is an amorphous polar thermoplastic polymer with great resistance to abrasion, corrosion and a wide range of chemical products. It has good impact resistance, low water absorption, low electrical conductivity and dimensionally stable.

Placement

- Extend abundant grip material on the surface where the floor is to be installed.

- Then, put the ceramic tiles right where you are going to put the profile.

- Dispense the profile longitudinally aligned with the corner of the baldasas and fasteners with cement.

- Continue adding the baldasas to the profile to complete the installation. Before the fraguado takes place, tap gently with a stick of gum to fit the profile with the floor if necessary.

- Finally clean the excess material and let it dry.

For its correct placement, it is recommended to follow the guidelines described in UNE 138002: 2017 “General rules for the ejecución of tiles with ceramic tiles for adherence”. According to the norm, we recommend the placement recommendations for the floor joints.

In general terms it is recommended:

- For exterior floors, it is recommended to close surfaces of between 10 and 25 m2 at the most, but the distance between the joints is greater than 5 meters.

- For indoor floors, with smaller thermal variations, it is recommended to close surfaces of between 50-70 m2 at most, without the distance between the joints being greater than 8 meters linear.

Cleanliness and maintenance

Cleaning must be carried out periodically with a soft cloth. If you choose to use a neutral cleaning liquid, clear it with cold water and dry it to remove excess moisture. The persistent success can be eliminated with cleaning agents suitable for slightly abrasive cleaning or with a neutral colored octopus grating. If you apply a preserving agent, in addition to leaving a thin layer of water repellent, you should also remember that it must not be yellow, attracting the octopus to success without having any effects.

It is not recommended to use steel wool, abrasive products or paint strippers like acid fuels (hydrochloric and perchloric), fuel bases (caustic soda or ammonia) or carbonated solutions. Also, citric acid must be used to remove the protective oxide layer from the aluminum surface. Waxes, petroleum jelly, lanolin are similar in sound. Avoid dissolving solvents with haloalkanes (hydrofluoroethers or chlorinated solvents) and fragrance accelerants containing chlorides (use accelerants without chlorides).