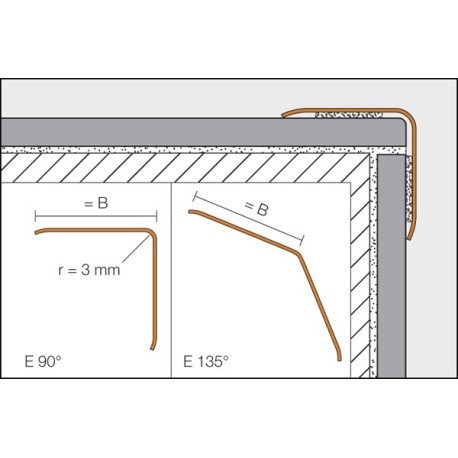

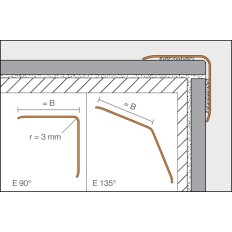

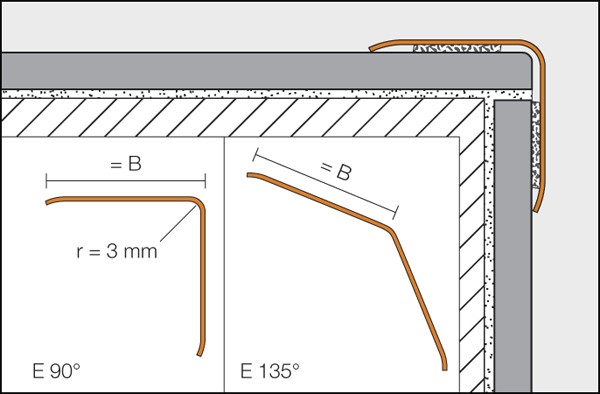

Corner profile that is subsequently installed to protect the external corners of tiled walls or other wall coverings. It offers excellent protection of edges that are subject to mechanical stresses, e.g. in industrial kitchens, meat processing plants, public bathrooms and hospitals etc. The profile covers damaged edges to avoid the need for replacement and remodelling. Schlüter ECK-K as an external wall corner can be combined with the cove shaped stainless steel profiles Schlüter®-DILEX-EHK as an internal corner and Schlüter DILEX-HKS as a floor/wall transition.

Cove shaped profile profile that is subsequently adhered at the internal corners of tiled walls or other wall coverings. The profile covers damaged spots or imperfect internal corners to avoid the need for replacement and remodelling. Pre-formed external and internal corners as well as connectors are available for the profile type Schlüter ECK-KHK.

Schlüter ECK-K /-KHK is particularly suitable for hygienically sensitive areas, where an appealing visual design is as important as ease of cleaning, e.g. in hospitals, industrial kitchens, clean rooms, washrooms, and in food preparation areas etc.

Schlüter ECK-KI is a stainless steel corner profile that is retrofitted to protect the internal corners of tiled walls or other wall coverings. The profile creates an appealing visual appearance and covers damaged spots or imperfect internal corners to avoid the need for replacement and remodelling.

Material

Edge profile made of stainless steel of material no. 1.4301 (V2A), while Schlüter ECK-K is also available in stainless steel material no. 1.4404 (V4A). The profiles are produced from steel strips in a roll forming process. The visible areas of the profiles are covered with a protective foil, which is removed after installation.

Material properties and areas of application:

In special cases, the suitability of a proposed type of profile must be verified based on the anticipated chemical, mechanical, and/or other stresses.

The profiles Schlüter ECK-K /-KHK /-KI made of stainless steel 1.4301 (V2A) as well as the profile Schlüter ECK-K, which is also available in stainless steel material 1.4404 (V4A), are particularly suitable for applications that require high mechanical durability and resistance to chemical exposure, for example to acidic or alkaline media or detergents.

Stainless steel is not resistant to all chemical stresses, and may be affected by hydrochloric and hydrofluoric acid or certain chloride and brine concentrations. Special anticipated stresses should therefore be verified in advance. Depending on the anticipated chemical stresses, customers can choose between the alloy materials 1.4301 or 1.4404 for the profile Schlüter ECK-K.

Installation

- Schlüter ECK-K /-KHK /-KI profiles are adhered to fully tiled wall corners with the installation adhesive Schlüter KERDI-FIX or an equivalent material. Apply one line of adhesive to the back of the profile’s anchoring legs and then press it onto the edge or corner or the covering in such a way that the lateral edges are fully attached. Prior to applying the installation adhesive, remove all substances that may weaken the bond (e.g. grease, etc.) from the attachment areas.

- Use a suitable detergent to remove all excess adhesive squeezed out from below the profile’s anchoring legs.

- Remove the protective foil.

Maintenance

Schlüter ECK-K /-KHK /-KI requires no special maintenance or care. Use suitable detergents to remove contamination as part of the regular cleaning of the coverings. The visible areas of the profiles can be polished with commercial chrome polishing products. Stainless steel surfaces exposed to the environment or aggressive substances should be cleaned periodically using a mild household cleaner.

Regular cleaning maintains the neat appearance of stainless steel and reduces the risk of corrosion. All cleaning agents must be free of hydrochloric acid.

Avoid contact with other metals such as steel, since this can cause extraneous rust. This also includes tools such as trowels or steel wool, i.e. tools used to remove mortar residue.