Application and Function

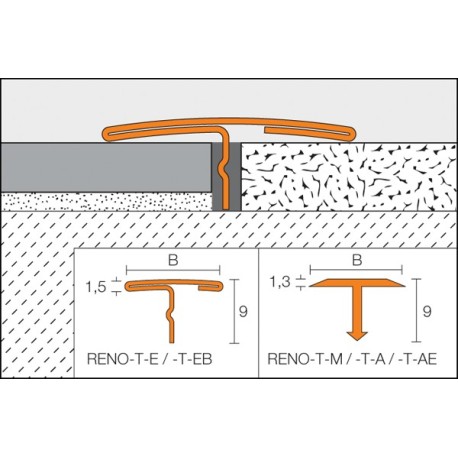

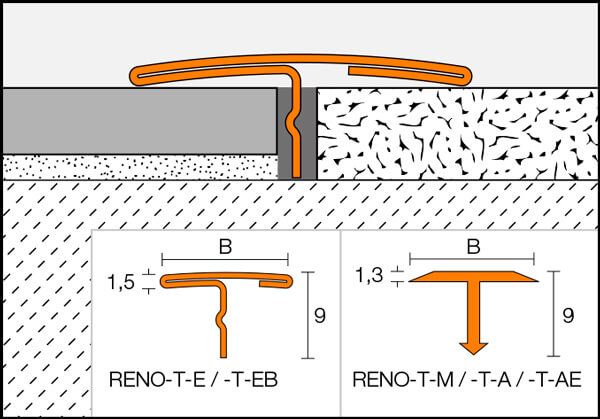

Schlüter RENO-T is a T-shaped profile installed as a transition between adjoining floor coverings of the same height e.g. ceramic tiles or natural stone, parquet flooring, concrete pavers, PVC laminate etc.

The void between the adjoining coverings is initially prefilled with the adhesive Schlüter KERDI-FIX or an equivalent to attach the Schlüter RENO-T profile, followed by pressing the spacer of the transition profile into the void.

Schlüter RENO-T overlaps the adjoining surface materials and thus prevents the edges from becoming damaged when subjected to mechanical stress.

Material

The profile is available in the following finishes:

- E = Stainless steel V2A (material no. 1.4301 = AISI 304)

- EB = Brushed stainless steel

- A = Aluminium

- M = Brass

- AE = Anodised Aluminium

Material properties and areas of application

Material properties and areas of application Schlüter RENO-T protects the edges of the covering materials against mechanical stress.

In special cases, the suitability of a proposed type of material must be verified based on the anticipated chemical, mechanical, and/ or other stresses.

Schlüter RENO-T-M are profiles made of brass. Minor manufacturing flaws are unavoidable on their untreated surfaces. An oxide layer forms on the visible surface of the brass profiles by exposure to air, which causes the surface to darken. Exposure to moisture or aggressive substances can reinforce the oxidation, resulting in stains on the profile surface.

Schlüter RENO-T-A are profiles made of aluminium. Minor manufacturing flaws are also unavoidable on their untreated surfaces. Technically, these are so-called semi-finished products, in which minor manufacturing traces also cannot be avoided.

For more demanding visual requirements, Schlüter RENO-T-AE or -EB with additionally treated, high-quality surfaces are available. The anodised aluminium finish of Schlüter RENO-T-AE can be damaged by aggressive substances or abrasive stresses.

Schlüter RENO-T-E and -EB are made of roll-formed stainless steel V2A (material no. 1.4301) and are particularly suitable for high mechanical impact or special exposure to chemicals. Application areas include the food industry, breweries, dairies, industrial kitchens and hospitals as well as residential spaces.

Even stainless steel is not resistant to all chemical stresses. Substances such as hydrochloric or hydrofluoric acid or certain chloride and brine concentrations may cause damage. Special anticipated stresses should therefore be verified in advance.

Schlüter RENO-T-E profiles have untreated surfaces, which may feature manufacturing- related continuous lines with varying intensity on the visible surface. For more demanding visual requirements, Schlüter RENO-T-EB with an additionally treated, high-quality surface is available.

Installation

- To install the Schlüter RENO-T transition profile, the joint cavity must be at least 9 mm deep and free from debris. Substances which inhibit adhesion must be removed from the sides of the joint.

- Prefill the joint chamber with Schlüter KERDI-FIX or an equivalent. Then press the vertical spacer of Schlüter RENO-T into the filled joint until the lateral spacers are flush with the edges of the covering.

- Remove any excess adhesive that is squeezed out from underneath the profile anchoring legs with a suitable detergent.

Maintenance

Schlüter RENO-T requires no special maintenance or care. The profile can be cleaned along with the covering, using suitable detergents.

The visible surfaces of the profiles can be polished with commercial chrome-polishing products. Stainless steel surfaces exposed to the environment or aggressive substances should be cleaned periodically using a mild household cleaner. Regular cleaning not only maintains the neat appearance of stainless steel, but also reduces the risk of corrosion. All cleaning agents must be free of hydrochloric and hydrofluoric acid.

Avoid contact with other metals, such as regular steel, to prevent corrosion. This also includes installation tools such as trowels or steel wool, e.g. for the removal of adhesive and grout residue. Do not use abrasive cleaning agents on the sensitive surfaces. We recommend the use of the stainless steel cleaning polish Schlüter CLEAN-CP.