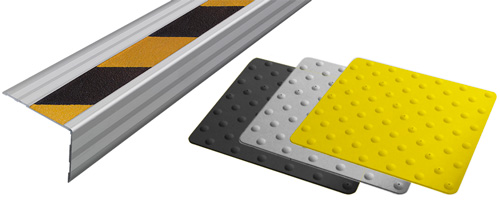

Plate made of matt silver anodized aluminum with colored non-slip band insert. This plate can be placed as a floor separating element, in entrances to establishments, on stair treads or on ramps.

Plate made of matt silver anodized aluminum with colored non-slip band insert. This plate can be placed as a floor separating element, in entrances to establishments, on stair treads or on ramps. The anti-slip band is classified as R13 in terms of anti-slip according to DIN 51130. Available with yellow, black, gray or yellow / black band.

Available with yellow, black, gray or yellow / black band.

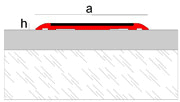

Dimensions

- a: 42 mm

- h: 2.5 mm

- Length: 2.50 ml

Applications

Plate made of matt silver anodized aluminum with anti-slip band insert available in five finishes. This plate can be placed as a floor separating element, in entrances to establishments, on stair treads or on ramps ... The anti-slip strip is classified as R13 in terms of anti-slip according to DIN 51130.

The contrast of the color band with the ground makes it an ideal element for placement in accessible environments where visual and / or tactile contrast is required.

Materials

Aluminum

The base of Novopletina Safety is a profile made using aluminum extrusion. The matte silver finish is anodized, improving through this process its resistance to corrosion, mechanical resistance and appearance.

Aluminum is a material with excellent chemical and physical-mechanical properties. It is light, tough, ductile, malleable and highly durable.

Anti-slip band

The Novopletina Safety band consists of aluminum oxide on a 0.1mm PVC backing. It resists outdoors, withstands water and motor oil and has a certified slip resistance under DIN51130 of R13, the highest in the range. The Novopeldaño® Safety anti-slip band helps to comply with the Accessibility Guide for buildings.

Technical characteristics and tests

- Alloy: 6063 / L-3441 - AA and ASTM / UNE 38-301-89

- Fire resistance: M0 / UNE 23-727-90

- Abrasion resistance: Very good

- Light fastness: Excellent

- Appearance and color: EN 12373-1

- Working temperature (*): - 30ºC / + 70ºC

- Water resistance (*): 10 months

- Chemical resistance (*): 8 months

- Motor oil resistance (*): Excellent

- Slip resistance (*): R13 / DIN51130

Installation

Novopletina Safety is placed on practically any support on finished work. You can put it in two ways:

- Adhesive: make sure that the profile and the support are clean and dry. Apply adhesive to the back of the profile and stick it directly to the desired location. We recommend the use of polyurethane putties or similar.

- Screwed: you can request the hole profile for mechanical fixings. You only have to mark the holes in the ideal position, place the profile and screw.

Cleaning and maintenance

Novopletina Safety is resistant to water and detergents. Cleaning should be carried out periodically with a soft cloth that does not release fibers. If you choose to use a neutral cleaning liquid, it must be rinsed with cold water and dried to remove excess moisture. Stubborn soiling can be removed with suitable mildly abrasive cleaning agents.

The use of steel wool, abrasive or pickling products, as well as strong acids (hydrochloric and perchloric), strong bases (caustic soda or ammonia) or carbonated solutions is not recommended. Citric acid should also not be used as it dissolves the protective oxide layer on the aluminum surface. Waxes, petroleum jelly, lanolin or the like are not suitable. Haloalkane solvents (hydrofluoroethers or chlorinated solvents) and setting accelerators containing chlorides should be avoided (use non-chloride accelerators).