DILEX-STF is a maintenance-free aluminum structural joint profile. The pre-assembled profile's fixing flanges are secured to the substrate with screws. The covering is then applied.

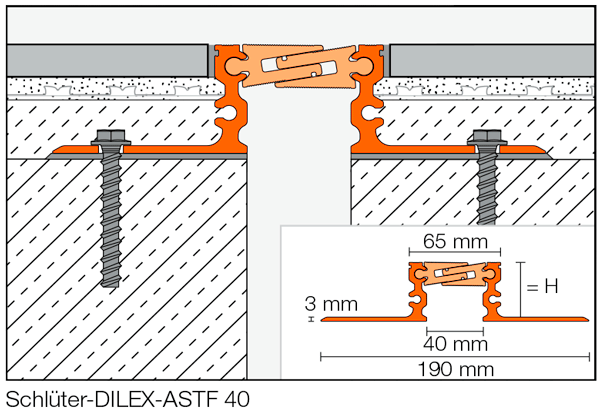

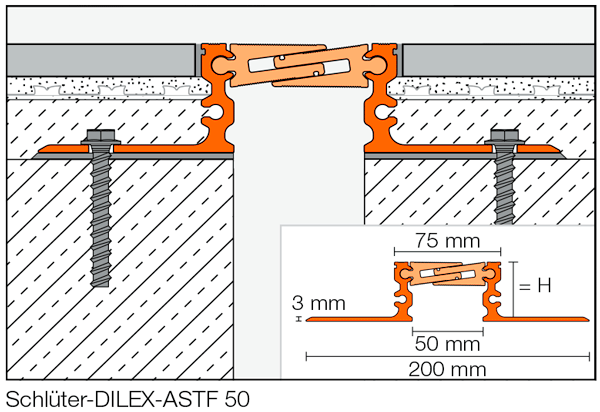

The tongue-and-groove central section allows for horizontal movement of ±6 mm (with a 40 mm joint width) or ±10 mm (with a 50 mm joint width). The lateral joints allow for three-dimensional movement, enabling tracking of the movement of the respective structural elements.

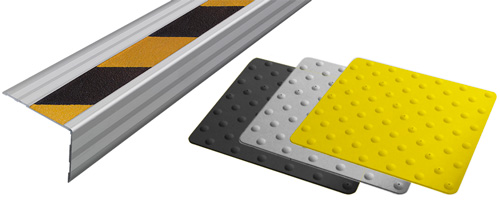

The DILEX-STF profile is designed for use in high-traffic areas with heavy pedestrian and industrial vehicle traffic, such as warehouses and production facilities, shopping centers, airports, train stations, parking garages, or areas that are machine-cleaned.

Material

The profile is available in the following finishes:

- A = Aluminum

Material properties and areas of application:

Schlüter-DILEX-STF profiles are made of aluminum. In the case of untreated aluminum metal surfaces, visual marks related to the production process, such as tool marks, are unavoidable. These characteristics are inherent to manufacturing and do not affect the functionality of the products.

The suitability of the DILEX-STF profile must be verified according to the expected chemical loads. Aluminum is sensitive to alkaline environments. Cement-containing materials, in combination with moisture, have an alkaline effect and, depending on the concentration level and exposure time, can cause corrosion (formation of aluminum hydroxide). Therefore, any traces of grout or adhesive must be removed from visible surfaces immediately. Newly laid tiles should not be covered with plastic. The profile must be installed avoiding gaps where alkaline water can accumulate.

Movement Absorption Capacity

| Compression | Tension | Level Difference | |

| DILEX-ASTF 40 | 6,0 mm | 6,0 mm | +/- 7,0 mm |

| DILEX-ASTF 50 | 10,0 mm | 10,0 mm | +/- 7,0 mm |

Installation

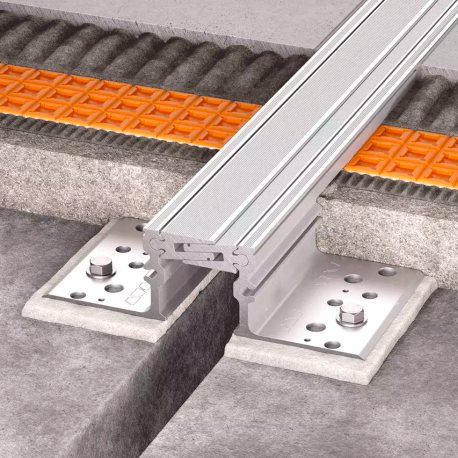

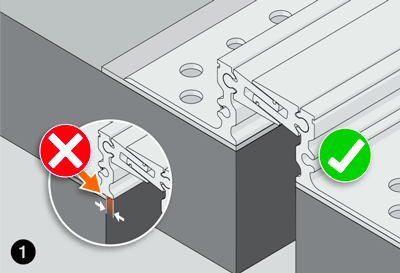

1. The designer's instructions must be taken into account when sizing the construction system. The profile must be selected based on the width of the structural joint and the construction height. The fixing flanges of the DILEXSTF profile must not encroach upon the width of the joint (see image 1).

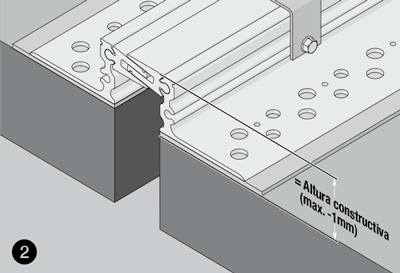

2. Irregular or low-profile substrates must be raised with a non-shrink mortar layer. In these cases, it is important to respect the entire width of the structural joint. If necessary, this must be ensured by using a suitable joint filling material.

3. Next, the DILEX-STF profile must be positioned so that the top edge of the profile is at the same height as the future flooring. The profile should never be higher than the surface of the covering, but rather approximately 1 mm lower (see image 2).

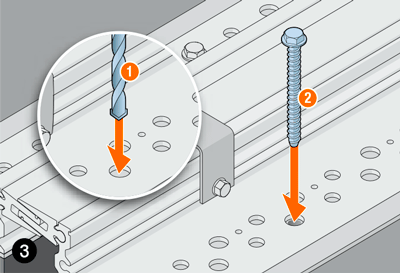

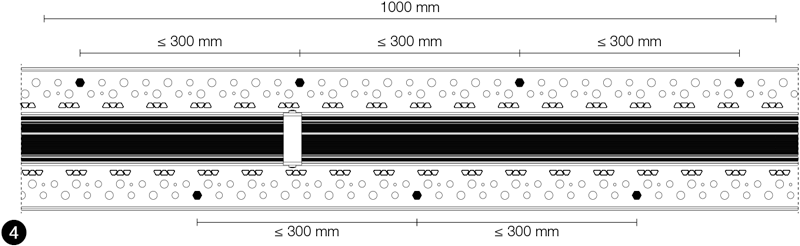

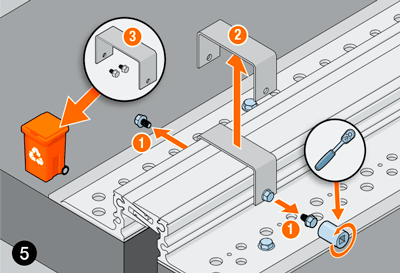

4. Anchoring on both sides is achieved exclusively through a mechanical connection with the structural element (see image 3). For this purpose, we recommend concrete screw anchors, such as the HECO MMS plus SS 7.5 x 80 vz, HECO MMS plus SS 10 x 70 vz, or equivalent versions. Always check the compatibility of the selected screw type with the substrate. The fixing points should be spaced at least 7 times per meter, or every 30 cm on both sides (see image 4).

Note: The pre-assembled clips must not be removed before or during profile installation and should only be removed after the profile has been securely attached to the substrate (see image 5).

5. The flooring installation can then proceed. It is important to ensure that the top edge of the profile aligns with the finished floor level and that sufficient space is left for the elastic grout. Make sure there are no gaps on the back of the tiles in the profile area. Always place the uncut side of the tile against the profile.

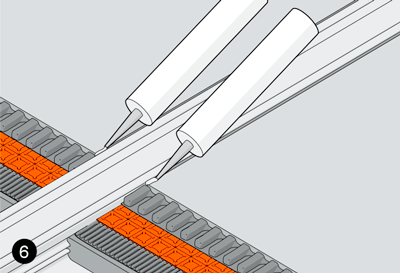

6. The joint between the covering and the profile must be completely filled with a neutral-curing elastic grout, and then the factory-supplied protective film must be removed from the profile immediately (see image 6).

Instructions

Schlüter-DILEX-STF requires no special maintenance or care. If an oxide layer forms on the aluminum, it can be removed with standard polishing products, but it will eventually reappear.